CNC Router

Tungsten Carbide End Mill

Carbide End MIll for Wood, Acrylic, Aluminum

1 Flute, 2 Flutes / Spiral / Upcut, Downcut / Compression

Size Unit: Diameter x Cutting Length x Shank x Overall Length mm

Material: Tungsten Carbide HRC55

The end mill products are made of tungsten carbide.

They are not HSS or carbide coated on HSS. The whole bit is made of carbide.

Carbide is alloy of carbon and iron, having 3~15 time more stronger than HSS

Usage: CNC Router for woodworking, wood cutting or engraving.

Why use Tungsten Carbide End Mill?

HSS(High Speed Steel): It is good for hand held trimmer or router, not for CNC.

Carbide is more suitable for CNC Router.

Carbide

Carbide bit is 3~15 times more stronger than HSS, and can work 2.5 times mroe faster.

It is necessarily recommended to use carbide bit for CNC Router woodworking.

Why use spiral bit?

Spiral bit is also necessary bit for the users who use a CNC Rouer for woodworking in these days.

Upcut or Downcut bit is commonly used, and needed almost 70% of woodworking.

Spiral bit gives much better cutting or engraving performance result than straight bit.

Upcut (for CNC, Trimmer or Hand held Rotuer)

Upcut (for CNC, Trimmer or Hand held Rotuer)

• The chips are discharged to upward so that chip emmission is good,

which means less load and less noise when it is used on CNC router.

• Therefore, can give fast feed speed

Cheap comparing with downcut or compression.

• There is 'bur' on the top surface.

• Usage: cutting, making a hole, etc.

Downcut (only for CNC)

• The chips are discharged to downward. There is no 'bur' on the top surface area.

• Expensive than Upcut. A little difficult to find a suitable RPM and Feed setting than Upcut.

• Usage: cutting or trimming, etc.

Compression (only for CNC)

• Upcut and Downcut are coexisted on Compression bit.

There is no 'bur' on the top and bottom surface area.

• Usage: best fo cutting a combination panel, laminated panel, etc.

Warning

• CNCer has to find a best RPM and Feed setting value for wood, CNC machine and bit type.

• There is no standardized RPM or Feed speed setting. CNCer has to find the best setting values by oneselves.

• End mill could be broken or burn becasue of inappropriate RPM ad Feed speed or too deep cutting depth.

• Do not recommend to cut too much deeper at a time. About 3~5mm at a time to cut.

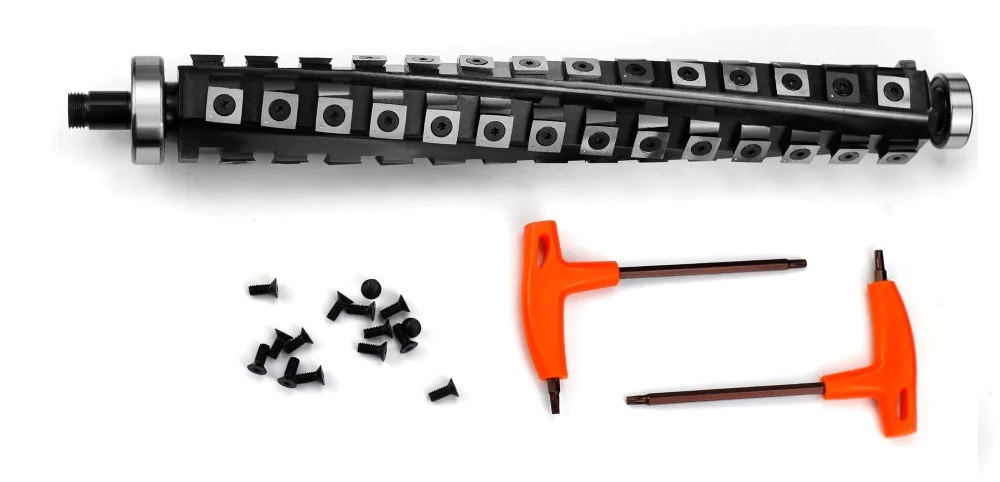

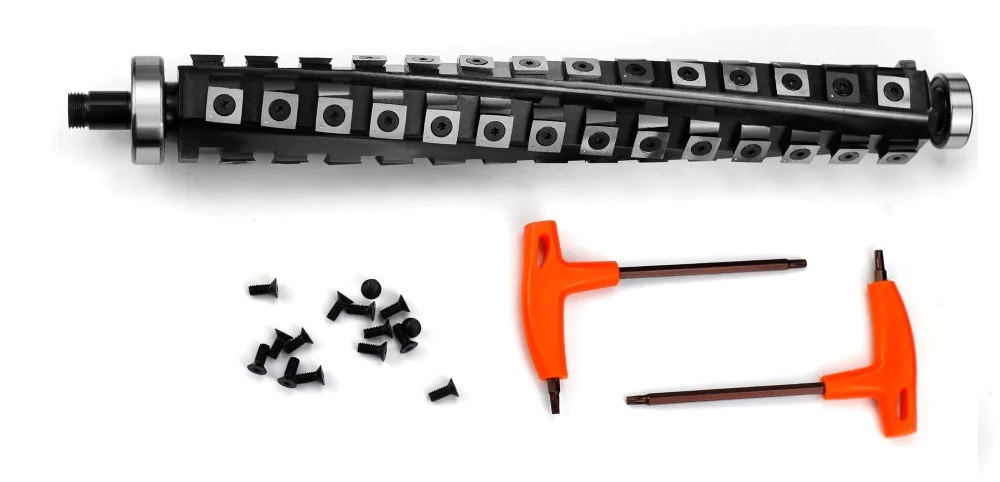

Dewalt DW735 13 inch Planer blade DIY replacement

UKR150 spiral helical cutter-head

4 rows of spiral heads and 58 inserts helical installed

Not protruding type, but buried type design!

Upgrade the Dewalt DW735 straight blade planer to a spiral + helical cutter-head!

Unlike other products that use a old-fashioned design with the insert blade protruding to the outside,

the insert blade safety is improved by adopting a buried design!

Why use a spiral and helical cutter-head?

It is a product designed by upgrading the protruding old-fashioned design of other companies on the market,

and it cuts more quietly and smoothly than any other products

by using a spirally inserted 4 row head and a helically mounted insert with an R value.

Product Components (Full Set)

◾1) Cutter-Head(with bearings installed) ◾2) 58 insert blades (buried design and helical mounted) ◾3) Free T-wrench ◾4) Exra free 5 insert blades

Details of each product component

Cutter-Head Body

◾Material: Steel Iron ◾Size Spec.: +/- 397.51 x 334.01 x 49.2mm ◾Weight: +/- 5kg

※ The cutter-head is 'sprial' with helically installed 58 carbide insert blades in 4 rows!!

※ Both sides of the cutter-head are equipped with bearings for easy replacement!!

Insert Blades

◾Size Spec.(width x length x thickness): 15 x 15 x 2.5mm . ◾Angle 30 degree R150

◾Insert Blade Material: Tungsten Carbide Hardness: HRA92.5 ◾Insert count: : 58 EA

※The inserts are helically installed to the cutter-head.

※All 4 sides of the insert blade have blades, so you can rotate and use the 4 sides of the insert blade.

※The inserts are not 'protruded', it is embedded in the cutter-head rows.

Screw for fixing the inserts

◾Material: Carbon steel black ◾Spec.: M5x16mm, ◾6 star Torx flat head

Advantages of 'Spiral Helical Cutter-Head'

Advantages of 'Spiral Helical Cutter-Head'

1) Low noise

2) The convenience and economy of managing and exchanging the inserts are good.

3) It has excellent durability and lifespan by using a carbide insert blade.

4) Excellent cutting result.

5) The overall cost is reduced by reducing electricity consumption.

Disadvantages of 'Spiral Helical Cutter-Head'

1) It cannot be re-polished. Actually no need to regrind. Just change the inserts.

2) The initial purchase price is expensive.

Old-Fashioned 'Extruded' vs New Upgrade 'Buried' Design

It has been upgraded by improving the exposed old-fashioned design with each insert blade protruding to the outside.

By adopting the 'recessed/closed/concealed/buried' design, the insert blade's safety has been improved.

Each insert blade can be rotated '4 sides'.

When using, use only one side of the 'blade', and the rest blades are 'recessed/buried'

The insert bloade is not exposed directly to the outside, reducing the risk of damage.

The R valued(R150) is included in the insert edge, so it cuts more smoothly and quietly than a regular insert blade without R value.

If you have more questions or inquiry for the products or cooperation, affiliate,

please send your email or INQUIRY FORM after filling it out. We will try to send our reply as soon as possible.

You can also purchase our prodcuts via our shops on the menu.